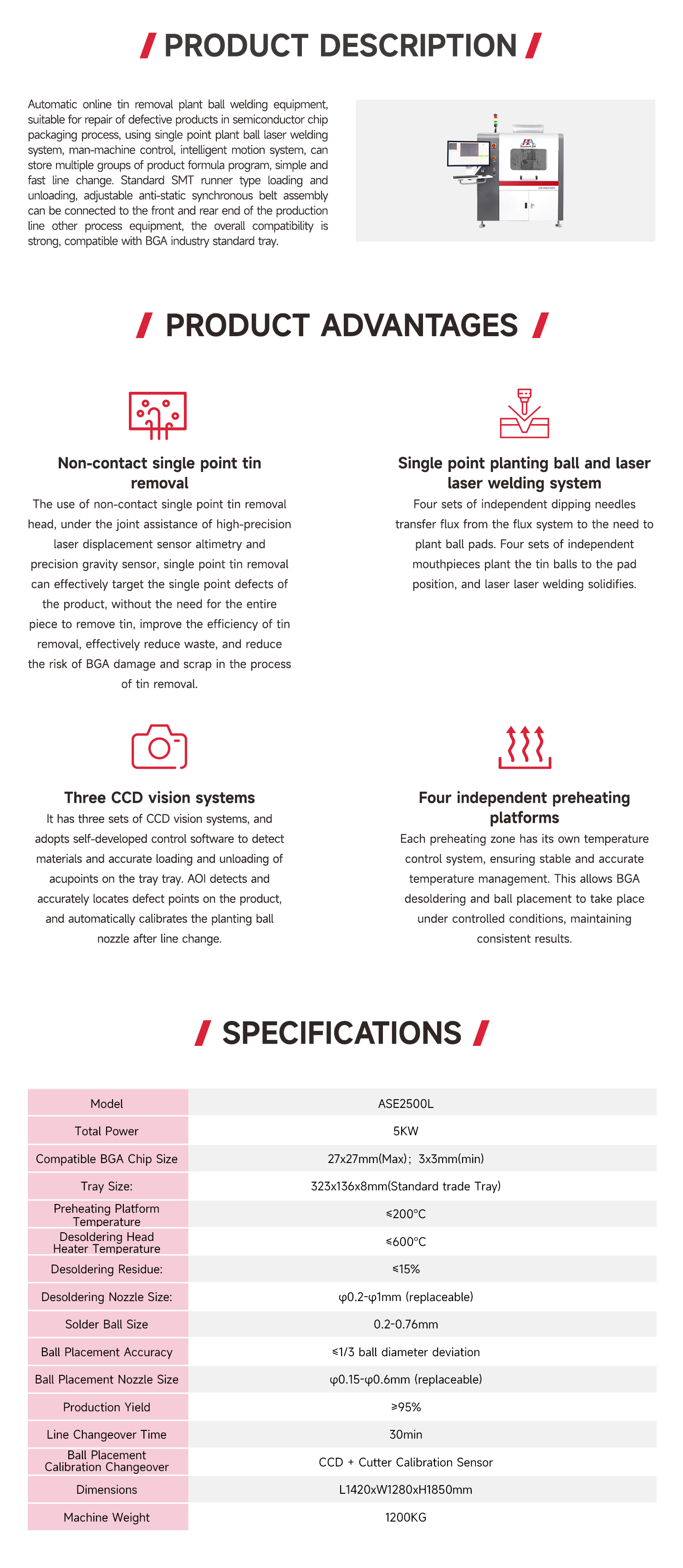

Fully automatic inline tin-removal/reballing/soldering equipment, suitable for repairing defective products in the semiconductor chip packaging process, using a single-point laser reballing and soldering system, human-machine control, intelligent motion system, can store multiple sets of product formula programs, simple line change and fast standard SMT runner-type loading and unloading, adjustable ESD synchronous belt components can be connected to other process equipment at the front and end of the production line, with strong overall compatibility, compatible with BGA industry standard trays.

| 型号 | ASE2500L | |

|---|---|---|

| Equipment Specifications | Total power | 5KW |

| Compatible BGA chip size | 27x27mm (Max); 3x3mm(min) | |

| Tray size | 323x136x8mm (standard industry tray) | |

| Preheating table temperature | ≤200°C (adjustable) | |

| Solder head heater temperature | ≤600°C (adjustable) | |

| Tin residue | ≤15% | |

| Desoldering nozzle | Φ0.2-Φ1 is replaceable | |

| Tin ball size | 0.2-0.76mm | |

| Ball planting accuracy | Deviation < 1/3 of the ball diameter | |

| Ball-planting suction nozzle | Φ0.15-Φ0.6 replaceable | |

| Production yield | Yield rate over 95% | |

| Line change time | 30min | |

| Replace the ball-planting nozzle for calibration | CCD+ Tool Setting Instrument Sensor Calibration | |

| Dimensions | L1420xW1280xH1850mm | |

| Weight | 1200KG |